How to choose the right panel to build the air ducts

5 key aspects every HVAC professional needs to know before choosing a pre-insulated panel

Choosing the correct panel for a pre-insulated air conditioning duct system is not a decision to be made lightly. The thermal efficiency, safety, durability of the system and also compliance with regulations, which are now essential in any serious project, depend on it.

In this article we present the 5 essential aspects that every professional in the HVAC sector should be clear about before choosing a pre-insulated polyurethane panel. If you are looking for reliability, efficiency and technical compliance, this is for you.

1. Foam must be PIR, not PUR

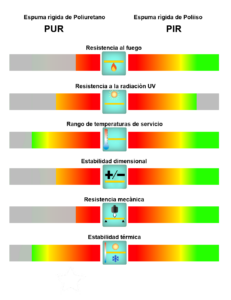

Although at first glance they may look similar, choosing between PIR and PUR foam makes a big difference in the behaviour of the channelling system.

The PIR foam is an evolution of the PUR and offers:

- Better fire resistance;

- Greater thermal stability over time;

- Greater compressive strength.

In short, a panel with a PIR core is safer, more efficient and more durable. There’s no going back: today the standard is PIR.

Comparison of the main properties between PUR and PIR

2. The coating must have an intact steam barrier

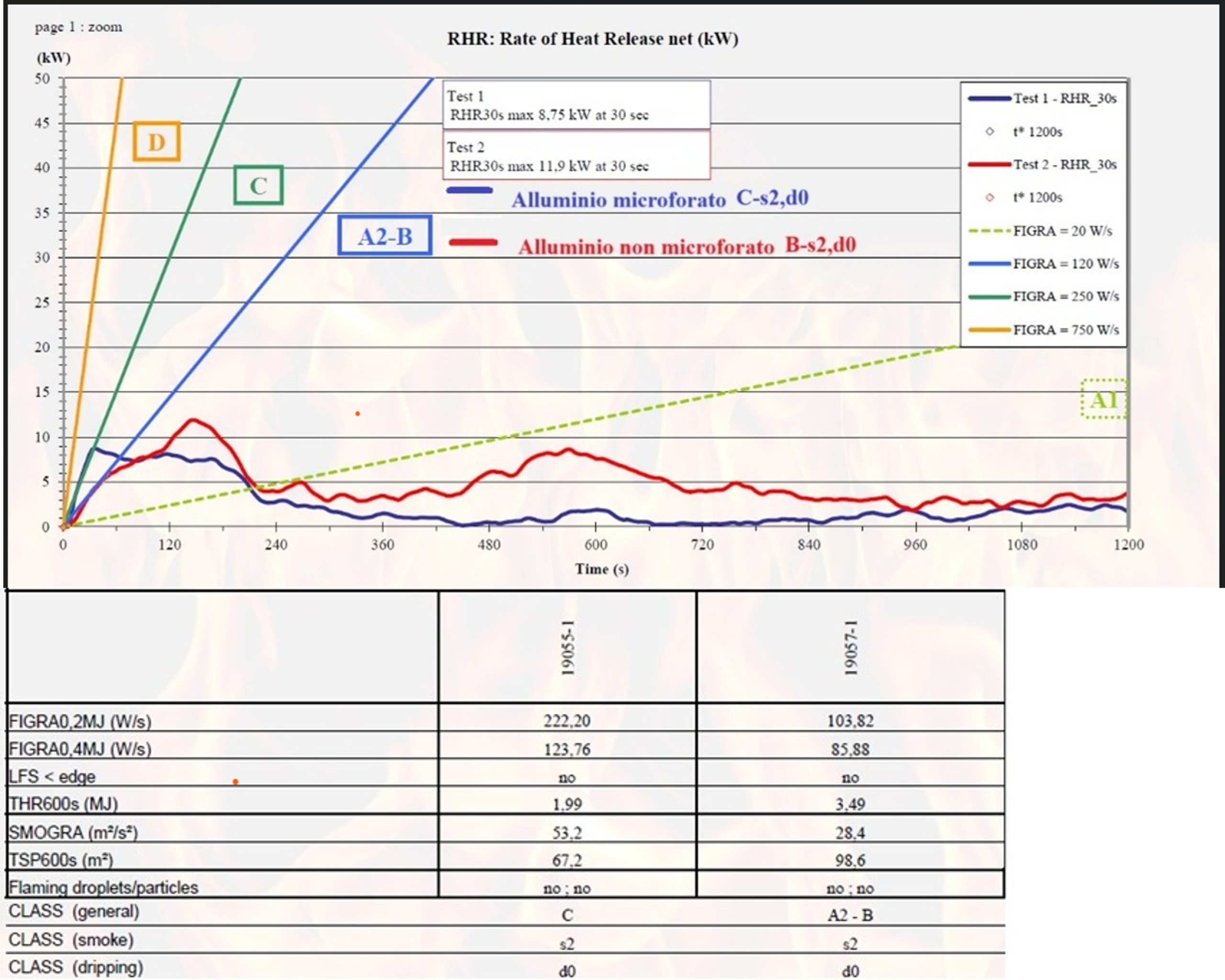

This is an often underestimated but fundamental aspect. The aluminum coating covering the panel is not only present for aesthetics: it acts as a barrier against steam.

But for it to perform its function properly, the aluminium foil must be perfectly intact, without any perforation or surface cutting. If this barrier is compromised:

- Surface or interstitial condensation may occur;

- The panel loses its thermal properties;

- Fire classification may be compromised;

- The energy efficiency of the system is reduced.

Also, make sure the panel can be cut cleanly and curved without breaking. Poor handling or fragile material compromises the entire installation.

Laboratory tests confirm: intact aluminium provides greater fire safety compared to perforated aluminium.

3. The panel must be certified according to recognized regulations

Having a certification essentially means that the product has been tested according to criteria of safety, efficiency and sustainability. In Europe, the most common and recognised standards for pre-insulated panels are:

- EN 13165: Thermal insulation products for building applications. Products made of rigid polyurethane (PU) foam;

- EN 13403: Ventilation of buildings. Non-metallic ducts. Duct networks made of insulating panels;

- EN 14308: Thermal insulation products for building and industrial systems. Rigid polyurethane (PUR) and polyisocyanurate (PIR) foam products.

However, they are not the only valid rules. The important thing is that the panel is certified according to internationally recognized regulations. Whether it is European, American or other, what matters is that it is based on strict and objective criteria that guarantee the quality of the product and its suitability for its intended use.

Choosing a certified panel means choosing safety, technical compliance and professional responsibility.

4. Must have an EPD (Environmental Product Declaration)

In a world where sustainability is no longer an option, pre-insulated polyurethane panels must also demonstrate their environmental impact. The best way to do this is through an EPD – Environmental Product Declaration.

This statement is based on a Life Cycle Analysis (LCA), a standardized scientific methodology that evaluates a product’s environmental impacts from production to disposal or recycling (Cradle to Gate, Cradle to Grave or Cradle to Cradle).

Thanks to the LCA it is possible to objectively evaluate:

- How much CO₂ the panel emits throughout its life cycle;

- How much energy it consumes;

- What is its footprint compared to alternative materials.

An EPD verified by third parties offers transparency, credibility and concrete data. This not only helps you meet increasingly demanding environmental requirements in public and private tenders, but also presents you as an up-to-date professional committed to sustainability.

5. The panel must come with a DoP (Declaration of Performance)

The Declaration of Performance (DoP) is a mandatory document for all CE marked products and must accompany the pre-insulated panel at the time of sale or installation.

This document clearly and transparently reports the main characteristics of the product:

- Fire resistance class;

- Heat conductivity;

- Compressive strength;

- Dimensional stability;

- Recommended applications.

DoP is an end-user guarantee and an essential tool for technicians, engineers and installers. It allows you to check if the panel is really suitable for the type of project in progress and facilitates technical decisions based on objective data.

In conclusion, not all polyurethane insulation panels are the same. If you want to ensure quality, efficiency and sustainability to your air duct system, be sure to check these 5 key points:

- PIR core with high thermal and mechanical resistance;

- Foil with intact and continuous vapour barrier;

- Internationally recognized regulatory certifications;

- LCA-based EPD to assess environmental impact;

- DoP that accompanies the product with all the technical data.

At STIFERITE, SpA we have been developing reliable solutions for the HVAC sector for years. Our Isocanale System built with our panels that isolate the air transport channel, not only meets these 5 requirements, but is also designed to simplify the work of the professional throughout the project, including all the accessories necessary for the construction of the air ducts.

There’s so much more to discover. Click to continue.